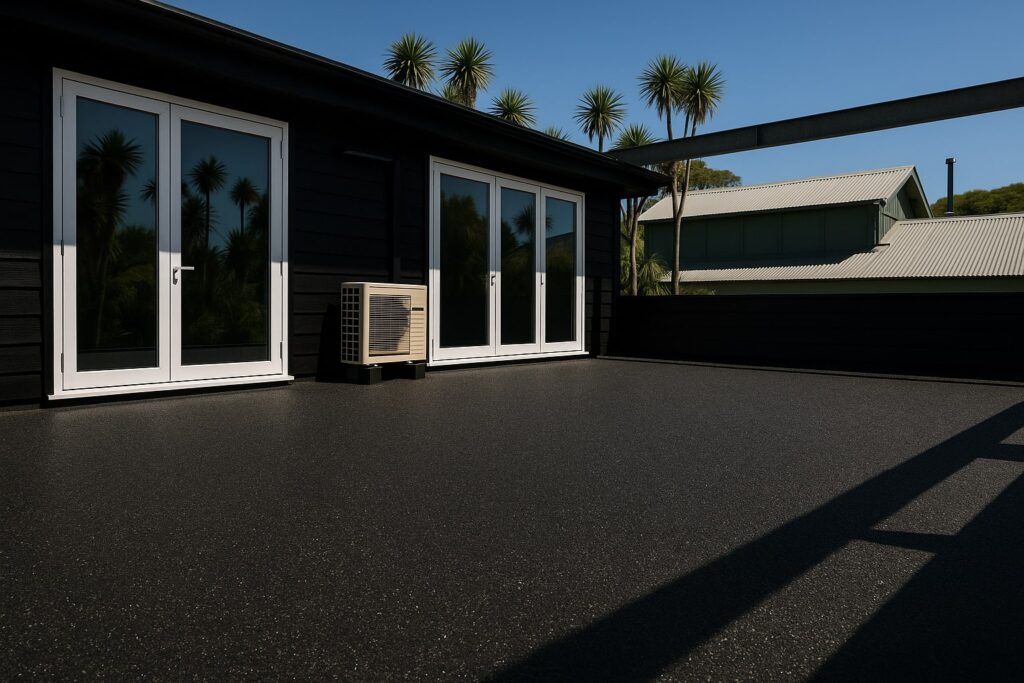

Roof waterproofing in Auckland keeps water out of your home by pairing the right membrane system with proper falls, outlets and detailing on flat and pitched roofs. We install BRANZ‑certified TPO, torch‑on, PVC and Butynol roof membranes designed for Auckland’s UV, wind and heavy rain, so your roof stays watertight, compliant and low‑maintenance for 20+ years.

Auckland’s Trusted Roof Waterproofing

Whether you’re building from scratch or upgrading an existing roof, we deliver an efficient, expert roof waterproofing service.

We can work in tandem with your construction team or oversee the entire waterproofing scope, guaranteeing meticulous attention to detail and superior standards.

Roof Waterproofing Solutions:

✓ Weather-resistant protection designed for Auckland’s climate

✓ UV-stable systems providing 20+ years of durability

✓ Seamless application perfect for complex roof shapes

✓ BRANZ-certified systems ensuring building code compliance

✓ Professional installation with comprehensive warranties

1. Auckland RoofS We Work With

Flat Roof systems

Flat roofs are a popular choice in construction, especially for commercial structures and some contemporary homes in New Zealand. Unlike traditional pitched roofs, flat roofs have a very slight slope (usually less than 10°) to allow for water drainage, but they appear virtually horizontal to the eye.

Pitched Roof solutions

Selecting the right pitched roof solution involves balancing aesthetics, durability, and weather protection. Trusted professionals will help specify the best materials, ensure correct installation, and apply waterproofing measures for Auckland’s climate.

Commercial Roof Applications

Commercial buildings in Auckland, including warehouses, offices, retail centres, and industrial facilities, present unique roofing challenges. Their roofs cover large surface areas and often need to support extra equipment, making performance and reliability paramount.

Residential Roof projects

A well-executed residential roof project in Auckland enhances both the beauty and economic value of your home, providing weather-resistant comfort for years to come.

2. Roof Waterproofing Challenges

- Weather-specific considerations

- Auckland’s subtropical climate presents unique challenges for roof waterproofing that require specialised solutions: Annual Rainfall Impact, Wind and Storm Exposure, UV Radiation Effects. Over 1,200mm of annual rain.

- Persistent humidity, ideal for mould and decay

- Common roof problems in Auckland

- Flat Roof Ponding, Roof Penetration Failures, Gutter and Parapet Issues.

- Leaks at joints and around penetrations

- UV-related membrane degradation

- Hidden rot or corrosion from ineffective detailing

- Climate-adapted solutions

- Drainage Optimisation, Material Selection, Installation Techniques.

3. Roof Waterproofing Process

- Inspection and assessment

- Comprehensive Roof Survey, Drainage Evaluation, Documentation.

- Comprehensive Roof Survey, Drainage Evaluation, Documentation.

- Preparation and installation

- Surface Preparation, Primer Application, Waterproofing Installation.

- Surface Preparation, Primer Application, Waterproofing Installation.

- Quality assurance

- Throughout the installation process, we conduct regular quality checks to ensure proper application, adequate thickness, and correct detailing.

- Throughout the installation process, we conduct regular quality checks to ensure proper application, adequate thickness, and correct detailing.

- Key NZBC clauses:

- E2 – is the New Zealand Building Code clause that deals with external moisture and keeping water out of the building.

- B2 – is the New Zealand Building Code clause for durability – it sets how long different building elements must last and remain fit for purpose.

4. Maintenance Programs

- Preventive maintenance schedules

- We recommend annual roof inspections, ideally before winter when Auckland’s heaviest rains arrive. These inspections identify potential issues before they become costly problems.

- We recommend annual roof inspections, ideally before winter when Auckland’s heaviest rains arrive. These inspections identify potential issues before they become costly problems.

- Early problem detection

- Regular gutter cleaning and drainage maintenance is essential in Auckland’s environment. We provide scheduled cleaning services and drainage system checks to prevent water backup.

- Regular gutter cleaning and drainage maintenance is essential in Auckland’s environment. We provide scheduled cleaning services and drainage system checks to prevent water backup.

- Long-term roof care

- Regular maintenance is significantly more cost-effective than emergency repairs or complete waterproofing replacement. Our programs are designed to minimise long-term costs while maximising protection.

5. Roof waterproofing membranes we install

- Torch-On Membranes best for large commercial roofs (Nuralite Nuraply, Viking Torch-On, Sealco)

- Durable traficable bituminous membrane, excellent for flat roofs and harsh weather.

- Learn more about Torch-On membranes

- TPO Membranes ideal for residential decks, parapets, flat roofs and large commercial roofs. (Viking Enviroclad, GAF, Nuralite, Sealco)

- UV-stable, eco-friendly, and suitable for diverse roof designs.

- Explore TPO waterproofing

- Butynol Membranes ideal for gutters, decks and flat roofs exposed to Auckland’s changing weather. (Ardex Butynol)

- Proven long-term performance for Auckland’s conditions.

- More on Butynol membrane

- Liquid-applied Membranes ideal for complex decks, balconies and roof areas where seamless detailing is critical. (Nuradeck, Nuradeck C)

- Durable liquid membrane ideal for complex deck shapes and detailing.

- More on Nuradeck membranes

6. Why Choose Us for Roof Waterproofing

- Local expertise and experience

- With over 20 years of experience specifically in Auckland’s climate, we understand the unique challenges local roofs face. Our team has worked on thousands of Auckland roofs, from heritage homes in Ponsonby to modern commercial buildings in the CBD.

- With over 20 years of experience specifically in Auckland’s climate, we understand the unique challenges local roofs face. Our team has worked on thousands of Auckland roofs, from heritage homes in Ponsonby to modern commercial buildings in the CBD.

- Certified installation processes

- We exclusively use BRANZ-certified waterproofing systems that comply with New Zealand Building Code requirements. This ensures your roof waterproofing meets all regulatory standards.

- Our team includes Licensed Building Practitioners (LBP) who oversee all waterproofing installations, ensuring compliance with building regulations and professional standards.

- We exclusively use BRANZ-certified waterproofing systems that comply with New Zealand Building Code requirements. This ensures your roof waterproofing meets all regulatory standards.

- Warranty and aftercare support

- We provide comprehensive warranties covering both materials and workmanship. Our warranties are backed by our established business and supported by manufacturer guarantees.

FAQ ROOF WATERPROOFING

For most roofs in Auckland, a torch-on membrane or a high-quality TPO membrane is the best waterproofing choice, offering long-lasting protection, UV resistance, and compliance with local standards.

Yes, a roof membrane should extend into the gutter for proper waterproofing.

Yes, you can apply a waterproofing membrane yourself, but professional installation is strongly recommended for roofs to avoid leaks and ensure warranties.

A quality waterproofing membrane lasts 20–30 years if properly installed and maintained.

A leaky roof is a major issue—left untreated, it can lead to extensive property damage, safety hazards, and expensive repairs. Immediate action is essential.

We also specialise in