Viking Enviroclad: Waterproofing Membranes for Flat Roofs

Auckland Waterproofing Experts

“The storm may roar above, but silence stays beneath with Viking Enviroclad.“

— Auckland Waterproofing Experts

Introduction

Modern architecture is driving a surge in flat and low-slope roof designs for both residential and commercial buildings. With these innovative layouts, waterproofing integrity becomes a crucial factor in construction and ongoing maintenance. Among the plethora of solutions available, Viking Enviroclad stands out as a premier, technologically advanced membrane system crafted specifically for such roof types.

Enviroclad isn’t just another waterproofing product; it integrates cutting-edge TPO (thermoplastic polyolefin) technology, mesh reinforcement, and a heat-weldable seams system—making it a robust choice for both new builds and renovations. This membrane offers adaptability across flat roofs, pitched roofs, gutters, and parapets, providing architects, builders, and property owners the flexibility they need in contemporary projects.

This comprehensive guide explores everything you need to know about Viking Enviroclad. We’ll break down its technical features, benefits, certifications, and provide actionable tips for installation and maintenance.

You’ll also discover how Enviroclad compares against other popular waterproofing membranes. Whether you’re an architect designing a new structure, a builder seeking best-in-class materials, or a homeowner planning a roof renovation, this guide delivers the insights you need to make informed decisions.

VIking TPO Membrane

What is Viking Enviroclad?

- Viking Enviroclad is a single-ply, polyester-reinforced TPO sheet membrane system designed for waterproofing flat and low-slope roofs.

- Developed and distributed by Viking Roofspec (New Zealand), it is installed on decks, parapets, gutters, and even pitched roofs for optimal water tightness.

At its core, Viking Enviroclad is constructed as a single-ply membrane featuring polyester fabric reinforcement embedded within the TPO material. This reinforcement provides critical tensile strength and puncture resistance, enabling the membrane to withstand the physical stresses encountered during installation and throughout its operational lifespan. The polyester mesh acts as a stabilising framework that prevents excessive expansion and contraction while maintaining the membrane’s structural integrity.

One of the most environmentally significant aspects of Viking Enviroclad is its complete recyclability. The TPO material contains no liquid plasticizers and excludes chlorine or chlorine-containing ingredients. This composition ensures that the membrane can be recycled during the manufacturing process, achieving 100% reuse of recycled material. Additionally, at the end of its service life, the membrane can be fully recycled, supporting circular economy principles and reducing landfill waste.

Membrane Composition

- Constructed from thermoplastic polyolefin (TPO), noted for its UV resistance and flexibility.

- Reinforced with polyester fabric, enhancing structural integrity.

- Seamless after heat welding, reducing risk of leaks.

- Available in standard and fleece-backed (FBS) options for specialised underlays.

Key Features and Benefits

Imagine stepping inside, knowing that every wall and ceiling is shielded by innovation designed to last.

Watertight Integrity

- Provides exceptional resistance to water ingress for low-slope and flat roofs.

- Heat-welded seams ensure the membrane is cohesive and seamless, increasing overall reliability.

The fundamental purpose of any roofing membrane is to provide reliable water exclusion, and Viking Enviroclad excels in this critical area. The membrane’s heat-welded seams create a continuous, seamless barrier that eliminates potential leak paths commonly associated with mechanically fastened or adhesive-bonded systems. This seamless construction provides absolute watertight integrity, even under challenging conditions such as ponding water or ice formation.

Durability and Longevity

- Offers a 20-year warranty when installed by a Viking Approved Applicator, reflecting long-term confidence.

- Resistant to UV, ozone, and atmospheric chemicals.

The membrane’s resistance to common causes of roofing failure sets it apart from alternative systems. Its UV resistance prevents polymer degradation that can lead to brittleness and cracking in exposed applications. Chemical resistance protects against damage from atmospheric pollutants, while puncture resistance helps prevent physical damage during maintenance activities or from falling debris.

Rapid Installation

The membrane’s design characteristics facilitate efficient installation while accommodating a wide range of architectural requirements. Viking Enviroclad is available in wide rolls up to 3.66 metres and long rolls up to 30.4 metres, minimising the number of seams required for typical installations. Fewer seams translate to faster installation times, reduced labour costs, and fewer potential failure points.

Sustainability

- Suitable for green roofing systems (plant-covered commercial or residential roofs).

- TPO is 100% recyclable post-lifecycle.

Viking Enviroclad’s environmental credentials align with contemporary green building requirements and sustainability objectives. The membrane’s 100% recyclable composition supports circular economy principles and reduces environmental impact. Manufacturing processes utilise recycled content, and end-of-life recycling prevents membrane disposal in landfills.

The system’s compatibility with green roofing applications further enhances its environmental benefits. When used as the waterproofing layer beneath planted roofs, Viking Enviroclad supports biodiversity, stormwater management, and urban heat island reduction while maintaining reliable waterproofing performance.

Certifications

- BRANZ appraisal guarantees performance in NZ conditions.

- CodeMark certified for regulatory compliance.

Viking Enviroclad’s comprehensive certification profile ensures compliance with New Zealand’s building regulations and provides confidence for specifiers and building consent authorities. The membrane holds BRANZ Appraisal No. 656, confirming its suitability for use as an alternative solution under the New Zealand Building Code. Additionally, CodeMark Certification No. 30058 provides verification that the system meets all relevant performance requirements for its intended applications.

Table: Key Features vs. Industry Norms

| Feature | Viking Enviroclad | Traditional Roofing Membranes |

| Warranty | 20 Years | 10–20 Years |

| Material Type | TPO, Polyester | Bitumen, Modified Bitumen |

| Seam Technology | Heat-welded, seamless | Torch-on, adhesive/seamed |

| UV Resistance | High | Varies |

| Sustainability | Recyclable | Limited |

| BRANZ / CodeMark | Yes | Not always |

Applications and Use Cases

Whether it’s the rooftop retreat where you savour morning coffees, the bustling deck that hosts family barbecues, or the workspace humming with creativity, every corner of your building deserves lasting protection.

VIking TPO Membrane

Residential Roofing

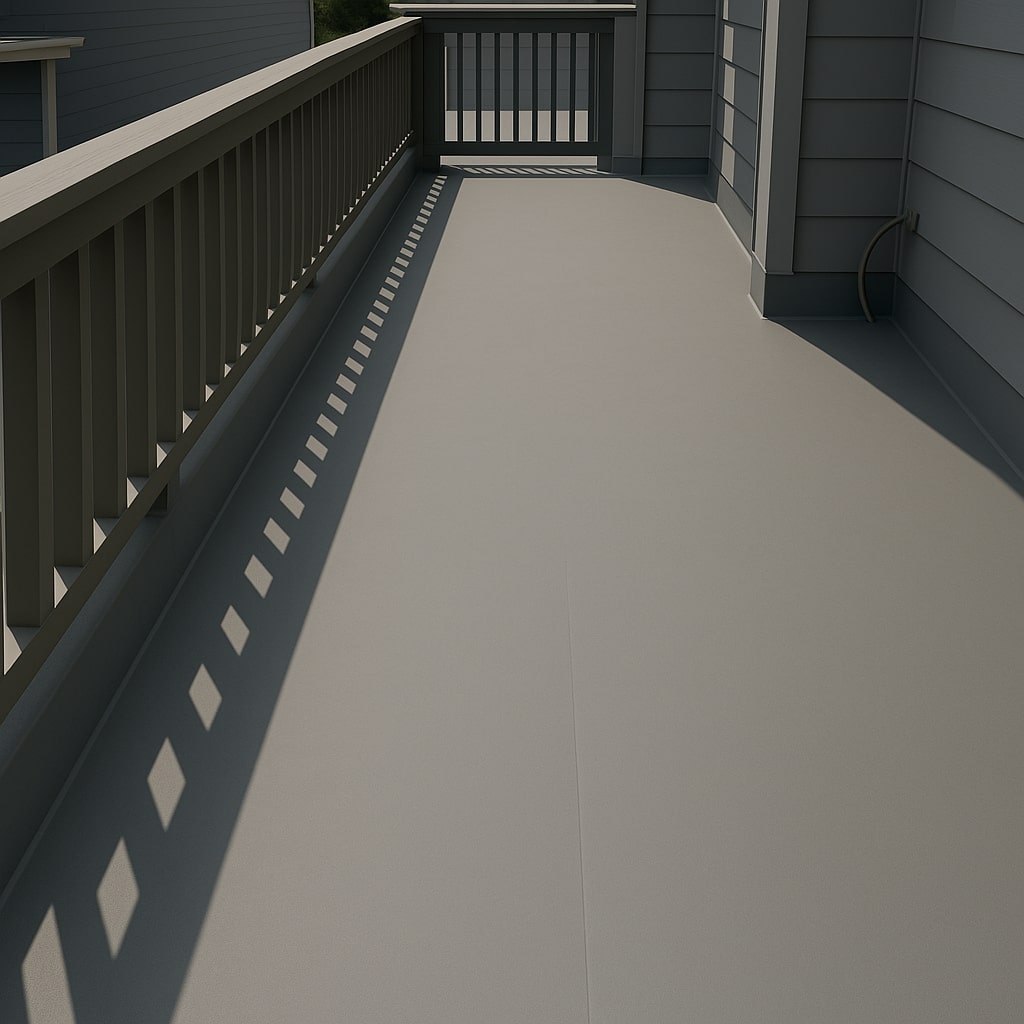

- Ideal for flat-roofed homes, decks, balconies, and parapets needing reliable, long-lasting waterproofing.

In residential construction, Viking Enviroclad addresses the growing trend toward flat and low-slope roof designs that characterise contemporary architectural styles. Modern homes increasingly feature flat roofed sections for aesthetic reasons, to accommodate rooftop equipment, or to create outdoor living spaces. The membrane provides reliable waterproofing for these applications while supporting additional functional requirements.

Commercial Roofing

Commercial roofing applications place demanding requirements on membrane systems in terms of performance, durability, and maintenance access. Viking Enviroclad addresses these requirements through its robust construction and proven track record in commercial installations across New Zealand and the Pacific Islands.

Industrial applications often involve exposure to chemical vapours, temperature extremes, and mechanical stresses that can challenge conventional roofing systems. Viking Enviroclad’s chemical resistance and thermal stability make it suitable for these demanding environments, while its proven durability reduces maintenance requirements and operational disruptions.

Green Roofing

- Compatible with living or planted roof systems, due to root barrier capabilities and chemical resistance.

Roof garden and green roof applications represent growing segments in sustainable construction where Viking Enviroclad provides critical waterproofing functions. The membrane serves as the primary waterproof barrier beneath extensive or intensive planted roof systems, protecting the building structure from water ingress while supporting the specialised requirements of living roof assemblies.

Gutters and Parapets

- Mesh-reinforced design makes it suitable for tricky roof details such as parapets and internal gutters.

Gutter and parapet waterproofing applications benefit from Viking Enviroclad’s ability to accommodate complex geometries and provide seamless transitions between horizontal and vertical surfaces. The membrane’s heat-weldable characteristics enable the creation of continuous waterproof details even in challenging configuration requirements.

Fleece-Backed System

- Viking Enviroclad FBS incorporates an added polyester ‘fleece’ layer for extra cushioning and compatibility with uneven surfaces.

Installation Process and Best Practices

“A home should be a haven—where laughter fills the air, and dreams take root beneath a sturdy roof. Yet, when sneaky leaks betray your trust, cherished memories risk being overshadowed by worries of rot and repair.”

The successful performance of Viking Enviroclad depends heavily on proper installation techniques and adherence to manufacturer specifications. Viking Roofspec’s requirement that all installations be completed by approved applicators ensures consistent quality standards and proper warranty coverage. Understanding the installation process helps building owners and project managers appreciate the importance of proper technique and quality control measures.

Substrate Preparation

Acceptable substrates include plywood, concrete, compressed fibre cement, and structural insulated panels (SIPs).

☆ Viking Enviroclad Substrate Checklist

Substrate evaluation involves assessment of structural adequacy, surface smoothness, moisture content, and compatibility with adhesive systems where applicable. The substrate must provide adequate support for the membrane system and any anticipated loads such as maintenance traffic, equipment installation, or green roof assemblies. BRANZ Appraisal No. 656 specifies that substrates must comply with Viking Roofspec’s masterspec specification requirements, and substrate checksheets must be completed to verify compliance before membrane installation begins.

Surface preparation requirements include cleaning to remove dust, dirt, oil, grease, concrete formwork release agents, and other contaminants that could interfere with adhesive bonding or membrane performance. Sharp edges, nibs, and surface irregularities must be addressed to prevent membrane damage during installation or service life.

Application Steps

- Surface cleaning: Ensure substrate is clean and dry.

- Primer/Sealer: Apply compatible surface sealer as per product technical data sheet.

- Membrane Placement: Roll out the Viking Enviroclad membrane and cut to fit.

- Fixing and Welding: Mechanically fix and heat-weld all seams for a watertight finish.

- Detailing: Pay attention to roof outlets, parapet caps, ventilation blocks, pipes, and drains.

- Inspection: Perform post-installation quality control using Viking’s checklists.

Quality control during installation includes continuous monitoring of welding parameters, visual inspection of completed seams, and destructive testing of sample welds to verify bond strength. Viking Roofspec provides comprehensive quality control checklists that must be completed during installation to ensure compliance with manufacturer specifications.

Best Practice Tips

- Minimize roof pitch at 2° or more to aid watershed.

- Angle fillets typically not required at upstands, simplifying detailing.

- Only use approved accessories and sealants for long-term reliability.

- Consult Viking’s comprehensive design and accessory documents for bespoke project solutions.

Successful Viking Enviroclad installations require careful attention to detail design and execution, particularly at complex geometries such as penetrations, roof outlets, parapet connections, and equipment supports. The membrane system includes a comprehensive range of accessories and installation details designed to address common roof configurations while maintaining waterproofing continuity.

Maintenance and Lifecycle

Maintenance Guide

- Regular inspections recommended, especially after significant weather events or impact damage.

- Minor repairs possible with heat-welded patches; avoid using non-compatible adhesives.

- Viking Roofspec provides a Care & Maintenance Guide to maximize membrane lifespan.

Common Issues & Solutions

- Punctures: Promptly repair with approved patch kits. Puncture damage represents one of the most common membrane maintenance issues, typically resulting from maintenance activities, falling debris, or equipment installation. Minor punctures can be effectively repaired using heat-welded patches that restore waterproof integrity without compromising surrounding membrane areas. Repair procedures must follow manufacturer specifications to ensure proper adhesion and long-term reliability.

- Detritus build-up: Clean regularly to prevent pooled water and substrate deterioration. Debris accumulation on membrane surfaces can interfere with drainage and potentially cause physical damage through abrasion or chemical interaction. Regular cleaning using appropriate techniques and materials removes accumulated debris while preserving membrane integrity. Cleaning procedures should avoid aggressive mechanical action or harsh chemicals that could damage the membrane surface.

- Seam checks: Inspect welds annually for any signs of lifting or separation. Seam separation may occur in limited situations due to installation deficiencies, substrate movement, or extreme exposure conditions. Early detection through regular inspection enables prompt repair using re-welding techniques or patch installation as appropriate for specific conditions. Seam repairs require proper surface preparation and welding procedures to achieve reliable results.

Certification, Appraisal, and Compliance

Regulatory Approvals

- BRANZ Appraised: independently tested to meet NZ Building Code requirements.

- CodeMark Certified: compliance for warranty and council sign-off.

- Approved for potable water applications – can be used on water tanks or reservoirs.

Comparing Viking Enviroclad with Other Roofing Membranes

| Membrane Type | Durability | Waterproofing | Sustainability | Installation Ease | Cost |

| Viking Enviroclad TPO | High | Excellent | High | Fast | $120–$200 per m² |

| Torch-on Bitumen | Medium | Good | Low | Moderate | $90–$140 per m² |

| PVC Membrane | Medium | Good | Medium | Fast | $95–$180 per m² |

| EPDM | High | Good | Medium | Moderate | $130–$220 per m² |

| Green Roof Specific | High | Excellent | High | Complex | $200–$400 per m² |

- Prices vary based on size, project complexity, insulation, and specific detailing requirements.

- Viking Enviroclad TPO sits at the mid–upper tier for quality and cost, reflecting premium technology and certifications.

- Green Roof systems are significantly pricier due to increased substrate, structural, and planting requirements.

Viking Enviroclad excels in rapid, heat-welded installation, eco-friendliness, and compliance certifications, making it a preferred choice for modern builds.

Conclusion

Viking Enviroclad offers a high-performance, reliable solution for waterproofing flat and low-slope roofs, decks, and parapets in the most demanding settings. Its combination of TPO technology, mesh reinforcement, and heat-welded seams means robust protection that lasts for decades. Whether you are specifying for a new architectural build, retrofitting an older structure, or upgrading to meet NZ construction codes, Enviroclad provides flexibility, sustainability, and peace of mind.

Coupled with best-in-class warranties, thorough testing, and regulatory certifications, Viking Enviroclad stands out as one of the most advanced roofing membranes available today. Make sure to consult with certified installers and refer to Viking’s detailed accessory guides for optimal results. With proactive maintenance, this system can protect your building investment for decades, making it a top choice for architects, builders, and property owners.

FAQs

Key Takeaways Summary

- Viking Enviroclad is a single-ply, polyester-reinforced TPO membrane for flat and low-slope roofs.

- Viking Enviroclad Substrate Checklist

- Delivers superior waterproofing, UV resistance, and is CodeMark and BRANZ certified.

- Comes with a 20-year warranty when installed by approved contractors.

- Compatible with green roofs, decks, and detailed roof features.

- Maintenance is simple, with Viking-approved guides and accessories for full lifecycle management.

- A sustainable, future-proof solution for modern residential and commercial projects.

- Check installation tips in this blog article ☆

Need a certified Viking Enviroclad installer?

Contact Auckland Waterproofing Experts today for your comprehensive roof assessment. Discover how Viking TPO Enviroclad can transform your flat or low-slope roof into a reliable shield against moisture, UV damage, and temperature extremes.

Your home represents your family’s future—protect it with roofing technology that delivers results for generations, not just years. The families who’ve already made this investment can attest: proper TPO waterproofing transforms vulnerable roof spaces into secure, energy-efficient protection while safeguarding the health and financial security you’ve worked so hard to build.

Don’t wait for the next storm. Viking Enviroclad is ready when Auckland’s weather isn’t.